Casting

Products

Products

주조는 재료를 융점보다 높은 온도에서 가열하여

액체로 만들어 거푸집에 부어 굳히는 가공 방법입니다.

액체로 만들어 거푸집에 부어 굳히는 가공 방법입니다.

Products

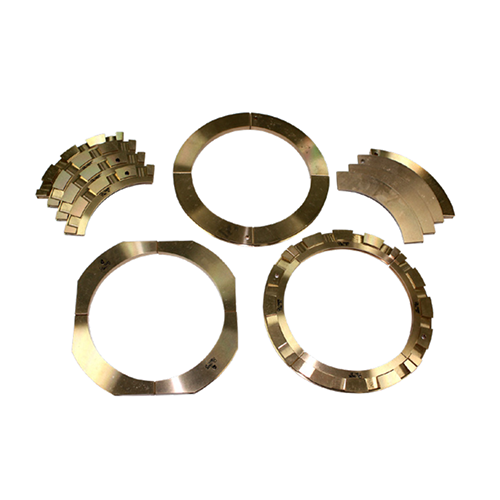

Segment

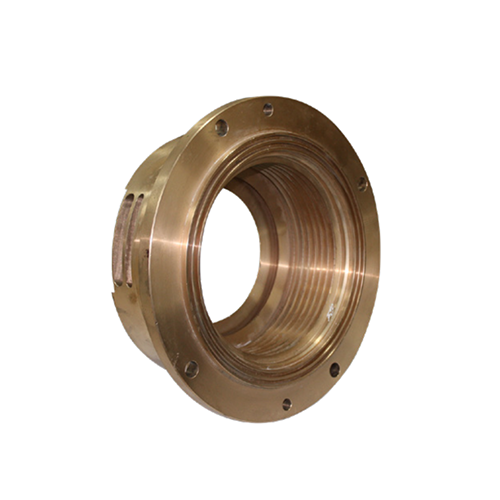

Bush

Oil labyrinth

Impeller

Specifications

| Classification | Shape | Size(mm) | Forged Weight | Remark |

|---|---|---|---|---|

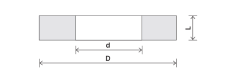

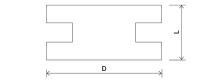

| Ring |

|

D : Max 2000 d : Min 50 T : Max 1500 | Max 2.5 Ton | Centrifugal Casting |

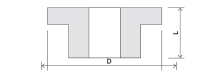

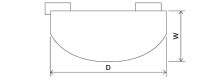

| Bush |

|

D : Max 2000 L : Max 1500 | Max 2.5 Ton | Centrifugal Casting |

| Valve |

|

D : Max 2000 L : Max 1500 | Max 2.5 Ton | Sand Mold Casting |

| Disk |

|

D : Max 1500 L : Max 2000 | Max 2.5 Ton | Sand Mold Casting |

Original Material

| Material | Jis spec | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Pb | Zn | Fe | Sb | Ni | P | Al | Si | Mn | |

| CAC301 (HBSC1) | 55.0-60.0 | 1.0 max | 0.4 max | 33.0~42.0 | 0.5~1.5 | 1.0 max | 0.5~1.5 | 0.1 max | 0.1~1.5 | ||

| CAC302 (HBSC2) | 55.0~60.0 | 1.0 max | 0.4 max | 30.0~42.0 | 0.5~2.0 | 1.0 max | 0.5~2.0 | 0.1 max | 0.1~3.2 | ||

| CAC303 (HBSC3) | 60.0~65.0 | 0.5 max | 0.2 max | 22.0~28.0 | 2.0~4.0 | 0,5 max | 3.0~5.0 | 0.1 max | 2.5~5.0 | ||

| CAC304 (HBSC4) | 60.0~65.0 | 0.2max | 0.2 max | 22.0~28.0 | 2.0~4.0 | 0.5 max | 5.0~7.5 | 0.1 max | 2.5~5.0 | ||

| CAC401 (BC1) | 79.0~83.0 | 2.0~4.0 | 3.0~70 | 8.0~12.0 | 0.35 max | 0.2 max | 1.0 max | 0.05max | 0.01 max | 0.01 max | |

| CAC402 (BC2) | 86.0~90.0 | 7.0~9.0 | 1.0 max | 3.0~5.0 | 0.2 max | 0.2 max | 1.0 max | 0.05max | 0.01 max | 0.01 max | |

| CAC403 (BC3) | 86.5~89.5 | 9.0~11.0 | 1.0 max | 1.0~3.0 | 0.2 max | 0.2 max | 1.0 max | 0.05max | 0.01 max | 0.01 max | |

| CAC406 (BC6) | 83.0~87.0 | 4.0~6.0 | 4.0~6.0 | 4.0~6.0 | 0.3 max | 0.2 max | 1.0 max | 0.05max | 0.01 max | 0.01 max | |

| CAC407 (BC7) | 86.0~90.0 | 5.0~7.0 | 4.0~3.0 | 3.0~5.0 | 0.2 max | 0.2 max | 1.0 max | 0.05max | 0.01 max | 0.01 max | |

| CAC502A (PBC2) | 86.0~90.0 | 9.0~12.0 | 0.3 max | 0.3 max | 0.2 max | 0.05 max | 1.0 max | 0.05~0.20 | 0.01 max | 0.01 max | |

| CAC502A (PBC2B) | 87.0~91.0 | 9.0~12.0 | 0.3 max | 0.3 max | 0.2 max | 0.05 max | 1.0 max | 0.15~0.05 | 0.01 max | 0.01 max | |

| CAC503A (PBC3B) | 87.0~91.0 | 12.0~15.0 | 0.3 max | 0.3 max | 0.2 max | 0.05 max | 1.0 max | 0.05~0.50 | 0.01 max | 0.01 max | |

| CAC701 (ALBC1) | 84.0~88.0 | 0.1 max | 0.1 max | 0.5 max | 1.0~4.0 | 0.1~1.0 | 8.0~10.0 | 0.1~1.0 | |||

| CAC702 (ALBC2) | 78.0~85.0 | 0.1 max | 0.1 max | 0.5 max | 2.5~5.0 | 1.0~3.0 | 8.0~10.0 | 0.1~1.5 | |||

| CAC703 (ALBC3) | 71.0~84.0 | 0.1 max | 0.1 max | 0.5 max | 3.0~6.0 | 3.0~6.0 | 8.5~10.0 | 0.1~1.5 | |||

| CAC704 (ALBC4) | 82.0~86.0 | 0.1 max | 0.1 max | 0.5 max | 2.0~5.0 | 1.0~4.0 | 6.0~9.0 | 7.0~15.0 | |||

| CAC602 (LBC2) | 77.0~81.0 | 9.0~11.0 | 4.0~6.0 | 0.1 max | 0.3 max | 0.3 max | 0.1 max | 0.1 max | 0.01 max | 0.01 max | |

| CAC603 (LBC3) | 77.0~81.0 | 9.0~11.0 | 9.0~11.0 | 0.1 max | 0.3 max | 0,5 max | 0.1 max | 0.1 max | 0.01 max | 0.01 max | |

| CAC604 (LBC4) | 74.0-78.0 | 70~9.0 | 14.0~16.0 | 0.1 max | 0.3 max | 0,5 max | 0.1 max | 0.1 max | 0.01 max | 0,01 max | |

| CAC605 (LBC5) | 70.0~76.0 | 6.0~8.0 | 16.0~22.0 | 0.1 max | 0.3 max | 0.5 max | 0.1 max | 0.1 max | 0.01 max | 0.01 max | |

| Material | Astm Spec | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Pb | Zn | Fe | An | Ni | S | P | Al | Si | Mn | |

| B61 (C92200) | 86.0~90.0 | 5.5~6.5 | 1.0~2.0 | 3.0~5.0 | 0.25 max | 0.25 max | 1.0 max | 0.05 max | 0.05 max | 0.005 max | 0.005 max | |

| B581 (C90300) | 86.0~90.0 | 7.5~9.0 | 0.3 max | 3.0~5.0 | 0.25 max | 0.25 max | 1.0 max | 0.05 max | 0.05 max | 0.005 max | 0.005 max | |

| B148 (C95400) | remainder | 3.0~5.0 | 3.0~5.0 | 2.5 max | 10.0~11.5 | 0.50 max | ||||||

| B148 (C95500) | remainder | 3.0~5.0 | 3.0~5.0 | 3.0~5.5 | 10.0~11.5 | 3.5 max | ||||||

| B148 (C95800) | remainder | 0,3 max | 3.5~4.5 | 3.5~4.5 | 4.0~5.0 | 8.5~9.5 | 0.10 max | 0.8~1.5 | ||||

| Material | Astm Spec | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Pb | Zn | Fe | An | Ni | S | P | Al | Si | Mn | |

| Ni-BRASS | 51.0~53.0 | 30.0~32.0 | 0.8~1.0 | 14.0~16.0 | 0.8~1.0 | |||||||

| NPB | 61.0~69.0 | 1.25~3.0 | 4.5~7 | 3.0~5.0 | 12.0~18.0 | 9.0~10 | ||||||